Now,

there are 2 methods for applying the Plastaweld. First we will

look at the hollow needle method. I am using a hypodermic

needle here, the sign industry also uses small plastic bottles

with hollow needles on top. either one works great.

in the photo to the right I am applying the powder to the

weld joint. It can be helpful to push the powder into the joint

after application using a pop sickle stick, razor blade or other

suitable tool.

Below, I am using another needle to saturate the powder with the

liquid. You want the powder fully saturated, but not washed away.

Let the weld cure until hard. This will take 5-20 minutes

depending on temperature.

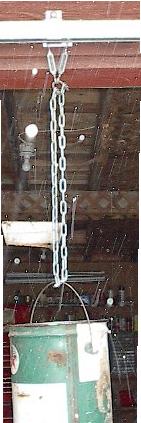

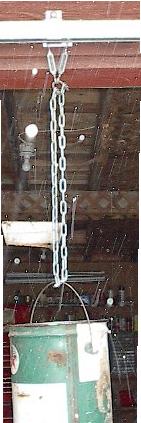

When

the weld is fully hardened, you may handle the piece. In order to

test the weld strength, I drilled two holes in the polycarbonate

and inserted turnbuckles. I then slid the piece into my garage

door rail. I attached a chain and a 5 gallon bucket to the

turnbuckles. I then slowly filled the bucket with bolts

watching for the point of failure so I could weigh the

bucket and document how much weight would cause a failure at the

weld. the bucket when full weighed 75 pounds, but the weld did

not fail. I then removed the bucket and suspended myself from the

chain. Still no failure.

I weighed in at 170 pounds

Tips For Successful plastawelding

- Due to it's powerful nature, the performance of

your Plastaweld will be affected by temperature. Controlling the

temperature will give more consistent results. When using in hot

temperatures, the product will sometimes gel to an unusable state

immediately when liquid and powder come into contact. To avoid

this problem, store product in a freezer and mix while still

cold. If Plastawelding job is in the field where a freezer is not

available, transport liquid and powder in a small cooler with Ice

packs. The professional results will be worth the

trouble.

-

- In very cold temperatures, cure times may be slowed

substantially. The curing process may be sped up by applying heat

with a blow dryer or heat gun. If using a heat gun use caution as

they can easily create enough heat to damage the product being

Plastawelded.

-

- Mix product in small quantities, as heat is generated

by the chemical process. This will cause the product to cure

before you are able to use it.

Please use your browsers back button to return to the home

page.

The Second

application method is the mix method.

Shown to the right, I pour a small quantity of powder into a

paper cup.

I then add enough liquid to over saturate the powder. if you add

to much liquid, you can add powder to thicken the liquid,

or if it is too thick to work with, add more liquid.

Later I will

determine a way to stress the part to the point of failure and

post the results.

Perhaps the engine test, but I don't think the garage rail

can stand it.

That speaks pretty well for the

Plastaweld.

Mix

with disposable tool and (after priming) apply to joint with rubber

gloved finger or other suitable tool.